DIY Low Cost Flexible Sticky PCB Fabrication

Zohar Messeca Fara | idiot.io 2020

| Materials: | Chemicals: | Tools: | Software: | |||

|---|---|---|---|---|---|---|

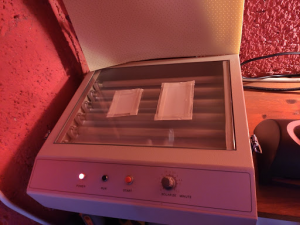

| Copper Tape 50mm Kapton Tape 50mm Masking Tape 20mm Sellotape (clear) A4 Printer Paper A4 pvc for laser printer Steel Wool | PhotoSensitive Dry Film Sodium Carbonate Ferric Chloride Citric Acid Acetone | Ruler (30cm) Precision Knife Scissors Laser Printer Laminator (A4) UV Box Etching Tank Timer Scale Disposable Gloves Kitchen Towel Cotton Ball | Inkscape |  | ||

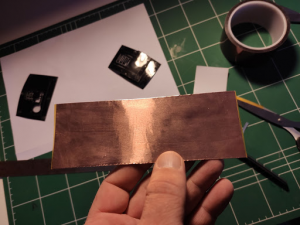

Process:

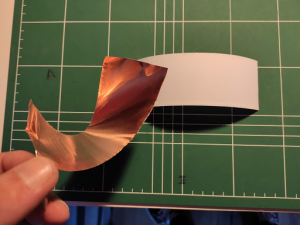

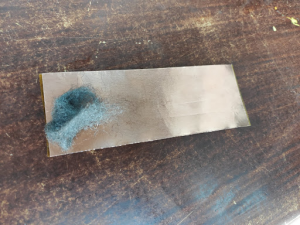

1 . Preparing Flexible Copper Tape Clad

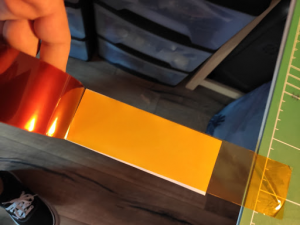

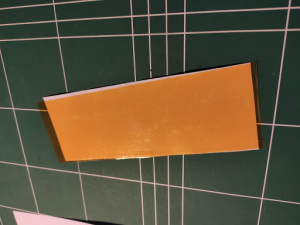

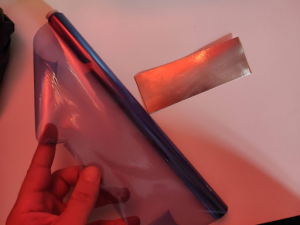

2 . Applying PhotoSensitive Dry Film on Flexible Copper Tape Clad

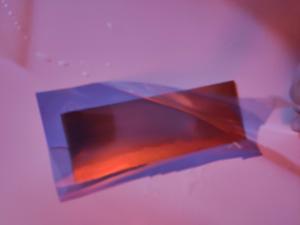

3 . Circuit PhotoMask Design and PhotoLithography Transfer

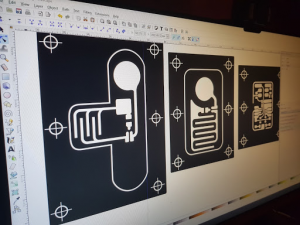

Circuit design is made with Inkscape a free open source vector graphics editor

Photolithography Technique uses UV light to transfer a geometric pattern from a photomask (also called an optical mask)

to a photosensitive (light-sensitive) chemical film on the substrate.

|  |  |

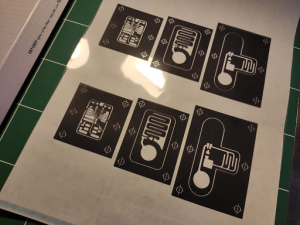

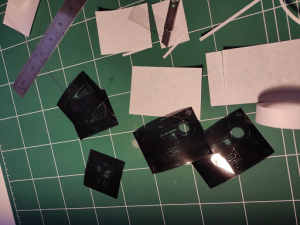

| a) Design your circuit graphicly with inkscape. | b) Duplicate Circuit design and print on A4 transparent PVC with a laser printer. | c) Cut PhotoMask use a precision knife and ruler. |

4 . Developing Process

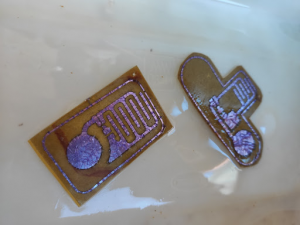

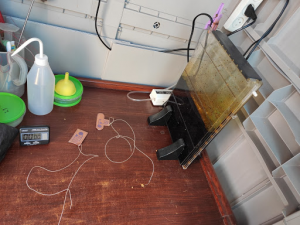

5 . Etching

|  |  |

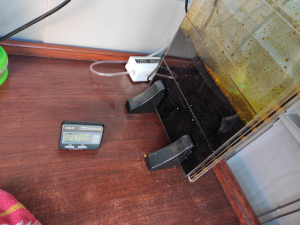

| a) We use ferric chloride as our etchant based on the Edinburgh Etch for Copper mix 1 liter saturated ferric chloride solution(40%) 200ml tap water, 66.6g citric acid working temperature 50C. work with disposable gloves on etching part! | b) Etching time takes around 7 - 20 min. depends on clad size and copper surface to etch. | c) Once Circuit is fully etched rinse it gently with water. Place Etched Circuit on a kitchen towel and let it dry. |